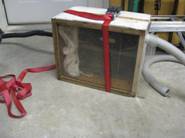

Vacuum Box

|

Here is my version of a vacuum box. I used two old medium boxes, two old inner covers, some screen and some scrap pieces of 3/4 x 3/4 wood. One box is the capture box, the other one mates up to it and is the vacuum side and storage for hoses when not in use.The plexiglass on the capture box slides in and out of 3 sides of an old inner cover that I glued and nailed to the capture box. The other side of the capture box is screened, and is inset to give me a better fit against the other medium. The first time I put the screen flat across, and it leaked way too much air so the vacuum didn’t work at the end of the hose. There is a hole drilled for the vacuum hose to suck up the bees. I use a peice of screen and some thumbtacks to hold the screen in place when the hose is not inserted. The old T-shirt is in there as a cushion so the bees don’t smack the far wall. If I properly adjust the vacuum strength via the bleed hole, I usually kill very few bees. The other box just has the old inner cover glued and nailed on and has a hole drilled to accept the shop vac hose.

By using a screen surface area this large, I can pickup a very large colony and not have a loss of vacuum as the box gets full. And yes, I have filled it up and had to use a second screened box.

The short hoses are corrugated for flexibility but smooth on the inside so as to not hurt the bees. They are in 2-1/2 foot sections for an outside Jacuzzi and just push together so I can keep it as short as possible for the job. Found them at a garage sale for $1 each. Makes it easy to adjust the hose to be as short as possible. I recently also picked up an old portable vac at another garage sale for $5 that had a perfect 4 foot hose on it with a tapered nozzle. I kept the hose and ditched the power unit.

After I vacuum them up, I remove the pickup hose and use thumbtacks to hold the screen over the hole, then turn off the shop vac and then take the ratchet strap off to separate the two boxes. The bees are in the side that has screen on one side the box and the sliding plexiglass on the other side. I put that box screen side down on bricks, place a deep on top with some comb or frames/foundation and then slide the door back about 2 inches. All other exits are closed off for a day. Often I’ll stick a quart feeder jar over the inner cover hole with HBH 1:1 in it and not put the telescoping cover on. A day later I lift the hive body (the bees moved up over the last 24 hours) off the screened bottom box, and replace it with a true screened bottom board and let them fly. I’ve only had 2 swarms leave after this process. I have also used a queen excluder between the hive body and the bottom board as a queen includer to prevent her from leaving.

The plexiglass lets me (and others) see how the bees are doing during the vacuum process, and it slides out so I have a way to release them into a hive body.

Glue all joints and or seal with caulk. You need a tight seal everywhere else so the only “air bleed” to control the strength of the vacuum is the designated one. The air bleed can be as simple as tape on the hole of the inner cover on the vacuum side and you cover or uncover to adjust the vacuum strength at the end of the hose. You want the vacuum at the end of the hose to just barely be strong enough to pull the bees in. Usually I keep it weak enough that if they have a good grip on the comb, they can hold on and not be sucked in. I just keep moving the tip of the hose around and they eventually get sucked up with minimal losses.